Choosing the right oval head cutter can make or break your heavy-duty tasks. I’ve seen how the wrong tool slows you down or ruins precision. That’s why I recommend High StrengthRound oval Head cutters. They’re durable and precise. Check out options at https://www.yunlanfastener.com/products for reliable choices.

Key Takeaways

- Strong oval head cutters are tough and very accurate. They are great for hard jobs.

- Pick the right material for your work: high-carbon steel is cheap, tungsten carbide is exact, and titanium-coated works well in heat.

- Clean and sharpen your cutters sometimes to keep them working well and lasting long.

Overview of Oval Head Cutters

What Are Oval Head Cutters?

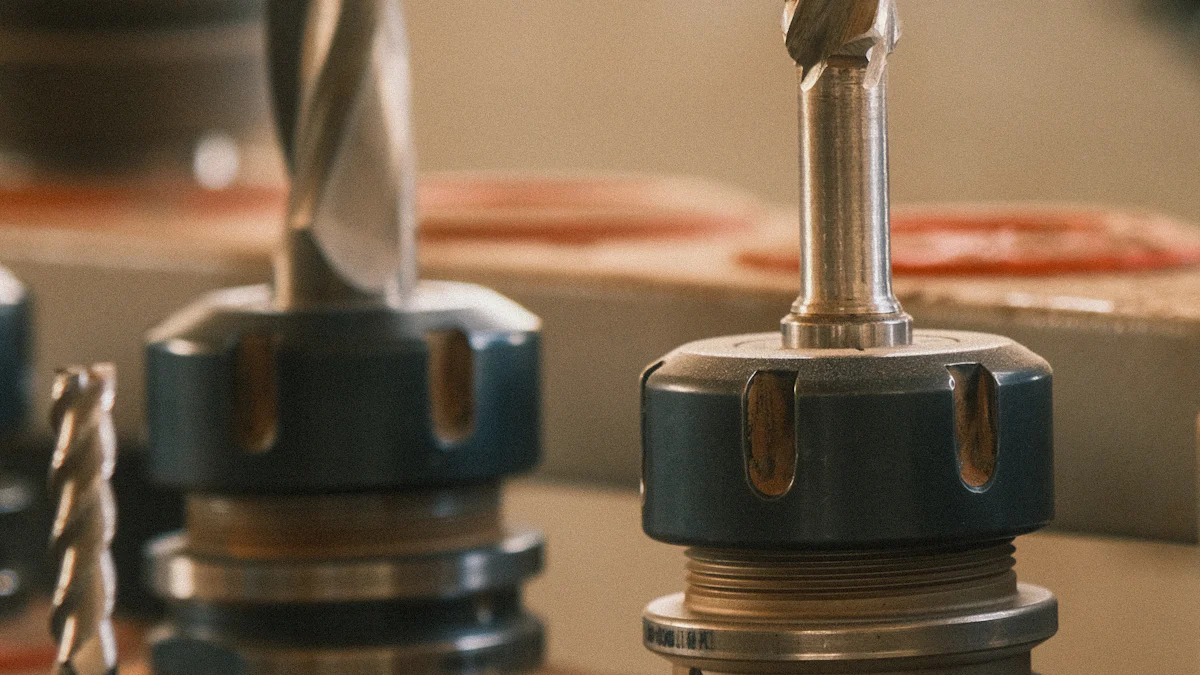

Oval head cutters are tools designed for precision cutting in tough materials. They have a unique oval-shaped head that provides better leverage and control compared to other cutter types. This design makes them ideal for tasks that demand accuracy and strength. I’ve found that their compact size and ergonomic grip make them easy to handle, even during long projects.

These cutters come in various materials, such as high-carbon steel, tungsten carbide, and titanium-coated options. Each material offers different benefits, but all aim to deliver durability and sharpness. If you’re working on heavy-duty tasks, you’ll appreciate how these cutters maintain their edge over time. The High StrengthRound oval Head cutters, in particular, stand out for their ability to combine strength with precision.

Common Applications in Heavy-Duty Tasks

Oval head cutters shine in a variety of heavy-duty applications. I’ve used them for cutting through thick wires, trimming metal sheets, and even shaping hard plastics. They’re also great for industrial tasks like electrical work, where precision is key. If you’re into DIY projects, these cutters can handle everything from crafting to home repairs.

Here’s a quick list of common uses:

- Cutting electrical wires and cables

- Trimming metal or plastic components

- Shaping materials for industrial or DIY projects

Their versatility makes them a must-have tool for professionals and hobbyists alike. Whether you’re tackling a big industrial job or a small home project, these cutters deliver reliable performance every time.

Types of Oval Head Cutters

High-Carbon Steel Cutters

High-carbon steel cutters are my go-to for durability and sharpness. They’re tough enough to handle heavy-duty tasks without wearing out quickly. I’ve noticed they stay sharp longer than other materials, which is a big plus when precision matters. Manufacturers can even tweak their properties through heat treatment, making them versatile for different needs.

Here’s why I like them:

- Enhanced Durability: They last longer, even with frequent use.

- Precision and Sharpness: Their hard edges cut cleanly and accurately.

- Customizable Properties: Heat treatment adjusts their strength and flexibility.

- Cost-Effectiveness: They perform well without breaking the bank.

If you’re looking for a reliable option that balances performance and price, these cutters are a solid choice.

Tungsten Carbide Cutters

Tungsten carbide cutters are all about precision and toughness. I’ve used them for tasks requiring extreme accuracy, and they never disappoint. They’re harder than most materials, which means they resist wear exceptionally well.

Here’s a quick comparison:

| Property | Tungsten Carbide (WC) | Titanium Carbide (TiC) |

|---|---|---|

| Hardness | 18-22 GPa | 28-35 GPa |

| Toughness | Higher toughness | Lower toughness |

| Wear Resistance | Lower than TiC | Better, especially at high temperatures |

These cutters are perfect for jobs where precision and durability are non-negotiable.

Titanium-Coated Cutters

Titanium-coated cutters bring a lot to the table. I’ve found them especially useful for high-temperature tasks. The coating reduces friction and increases hardness, which improves cutting performance.

Here’s what makes them stand out:

- Titanium carbo-nitride (TiCN) enhances cutting at lower temperatures.

- Titanium nitride (TiN) boosts wear resistance and tool life.

These cutters last three to four times longer than uncoated tools. They’re a great pick for cutting aluminum or steel alloys.

Alloy Steel Cutters

Alloy steel cutters are built for strength and longevity. I’ve seen them perform well in demanding environments. They cost more upfront but save money in the long run because they require less maintenance.

Here’s why they’re worth considering:

- Increased lifespan due to wear-resistant elements like chromium.

- Ability to handle extreme conditions without breaking down.

- Tailored strength for high-stress applications.

If you need cutters for heavy-duty or high-performance tasks, alloy steel won’t let you down.

Performance Comparison

Durability and Resistance to Wear

When it comes to durability, I’ve noticed that not all cutters are created equal. High-carbon steel cutters hold up well under heavy use, but tungsten carbide cutters take the crown for wear resistance. They’re incredibly tough and can handle repeated use without losing their edge. Titanium-coated cutters also stand out. The coating adds an extra layer of protection, making them ideal for high-friction tasks.

If you’re like me and hate replacing tools often, you’ll appreciate the longevity of alloy steel cutters. They’re built to last, even in extreme conditions. The High StrengthRound oval Head cutters, in particular, combine durability with precision, making them a reliable choice for demanding jobs.

Cutting Precision and Efficiency

Precision is everything when you’re working on detailed tasks. I’ve found tungsten carbide cutters to be the most accurate. They slice through materials like butter, leaving clean edges every time. Titanium-coated cutters also perform well, especially when working with metals.

For efficiency, high-carbon steel cutters are a solid option. They’re sharp and get the job done quickly. However, if you’re tackling intricate projects, the High StrengthRound oval Head cutters offer the perfect balance of precision and speed.

Maintenance and Longevity

Nobody wants to spend hours maintaining their tools. That’s why I prefer cutters that require minimal upkeep. Tungsten carbide and titanium-coated cutters are low-maintenance champs. They resist wear and corrosion, so you don’t have to sharpen them as often.

Alloy steel cutters might need a bit more care, but their extended lifespan makes up for it. Regular cleaning and occasional sharpening keep them in top shape. If you’re looking for a long-term investment, these cutters are worth it.

Cost-Effectiveness

Price-to-Performance Ratio of High-Carbon Steel

High-carbon steel cutters are a budget-friendly option that doesn’t skimp on performance. I’ve used them for countless projects, and they always deliver solid results. Their sharpness and durability make them a great value for the price. You don’t have to spend a fortune to get reliable cutters that last.

For heavy-duty tasks, these cutters hold their edge longer than cheaper alternatives. That means fewer replacements and more savings over time. If you’re looking for a dependable tool without breaking the bank, high-carbon steel cutters are a smart choice.

Price-to-Performance Ratio of Tungsten Carbide

Tungsten carbide cutters might cost more upfront, but they’re worth every penny. I’ve found their toughness unmatched, especially for precision work. They resist wear better than most materials, so you won’t need to replace them often.

Think of them as an investment. While the initial price is higher, their longevity and performance save you money in the long run. If you need cutters for demanding jobs, tungsten carbide is a no-brainer.

Price-to-Performance Ratio of Titanium-Coated Cutters

Titanium-coated cutters strike a perfect balance between cost and performance. I’ve noticed they last three to four times longer than uncoated tools. That’s a big deal when you’re working on high-temperature tasks.

Here’s why they’re a great value:

- Titanium Carbo-Nitride (TiCN) reduces friction and increases hardness.

- Better lubricity improves cutting performance and chip removal.

- Lower operating temperatures make them ideal for machining aluminum and steel alloys.

These features make titanium-coated cutters a cost-effective choice for industrial applications. They perform well and save money on replacements.

Price-to-Performance Ratio of Alloy Steel Cutters

Alloy steel cutters are a premium option, but they deliver exceptional value. I’ve used them for high-stress applications, and they never let me down. Their wear-resistant elements, like chromium, extend their lifespan significantly.

While they cost more upfront, their durability means fewer replacements. Over time, that adds up to big savings. If you need cutters for extreme conditions, alloy steel is worth the investment.

Best Use Cases

Ideal Cutters for Industrial Applications

When it comes to industrial work, I always look for cutters that can handle tough conditions without breaking down. High-carbon steel cutters are my top pick for general tasks. They’re durable and sharp, making them perfect for cutting wires, cables, or even trimming metal sheets. For more demanding jobs, like precision cutting in manufacturing, tungsten carbide cutters shine. Their wear resistance and toughness make them a reliable choice for repetitive, high-stress tasks.

If you’re working in environments with extreme temperatures, titanium-coated cutters are a game-changer. They reduce friction and stay sharp longer, even under intense heat. I’ve seen them perform exceptionally well in machining aluminum and steel alloys. For heavy-duty applications, alloy steel cutters are unbeatable. They’re built to last and handle high-stress conditions with ease.

Best Options for DIY and Hobbyist Projects

For DIY enthusiasts and hobbyists, I recommend tools that balance performance and ease of use. High-carbon steel cutters are great for small projects. They’re affordable and sharp enough to handle tasks like cutting wires or shaping plastic. If you’re into crafting or detailed work, tungsten carbide cutters offer unmatched precision. They leave clean edges, which is essential for intricate designs.

Titanium-coated cutters are another excellent option. They’re lightweight and easy to handle, making them ideal for extended use. Whether you’re building a model or repairing something at home, these cutters deliver consistent results. I’ve found them especially useful for cutting softer metals and plastics.

After comparing these cutters, I’ve found that the best overall choice for heavy-duty tasks is the High StrengthRound oval Head cutter. It checks all the boxes:

- Extra-large oval head for cutting thick wires

- ESD-safe ergonomic grips for comfort

- Forged steel construction for durability

- Flush cutting edges for precise results

Its cutting capacity ranges from 0.3 mm to 2.0 mm, making it versatile. Dual leaf springs ensure smooth operation, while the screw-joint construction adds stability. Plus, it’s rigorously tested for top-notch performance.

Ultimately, the right cutter depends on your needs and budget. Whether you’re a pro or a DIYer, pick the one that fits your tasks best.

FAQ

What makes High StrengthRound oval head cutters different from others?

High StrengthRound cutters stand out for their forged steel construction, ergonomic grips, and precise cutting edges. They’re built for durability and comfort, even during tough tasks.

Post time: Jan-30-2025